It can cut a variety of complex shapes of workpieces, and has the advantages of fast cutting speed, high efficiency, good cutting surface quality, accurate cutting size, and small thermal deformation of the workpiece. The cut parts can be directly welded and applied without machining. But CNC plasma cutting machine uses plasma arc to cut, which is compared with oxygen cutting. There are still some shortcomings, mainly reflected in the large inclination of the cutting surface, the finish is not as good as that of oxygen cutting. The main criteria for evaluating the quality of CNC plasma cutting are: the inclination of the cutting surface, the depth of the kerf cut, and the amount of dross. A high-quality cutting surface should have an inclination of less than 30, and a cut depth of 0. Less than 15mm, and less dross, easy to remove. In the condition of stable voltage and current, in addition to the quality of the electrode and the nozzle, the factors affecting the cutting quality mainly have two reasons: one is the cutting nozzle height and stability; the other is the matching of the cutting speed and the working pressure.

When the height of the cutting nozzle from the steel plate is controlled by the arc pressure height adjuster, its dynamic positioning accuracy can reach ± 0.013, so it can ensure that the height of the cutting nozzle and the steel plate remains unchanged, so the slope of the cutting surface is small It is uniform and has a good finish. When manually adjusting the height of the cutting nozzle from the steel plate. The cut steel plate should be leveled as far as possible to reduce the adjustment times of the cutting torch. Ensure the stability of the cutting torch. In this paper, the height of the cutting nozzle from the steel plate is controlled by 6 ~ 8mm by manual adjustment. Through a series of cutting experiments, the relationship between cutting speed (dirty), working pressure (P) and cutting quality is explained.

Through analysis and summary, the optimal cutting parameters for cutting different thickness steel plates with different powers were obtained. Provide reference for improving the cutting quality of CNC plasma cutting machine.

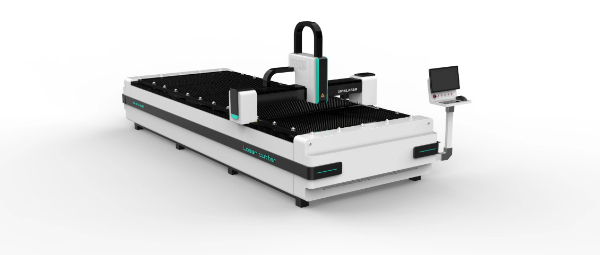

CNC plasma cutting machine is a kind of advanced mechatronics equipment used for blanking and cutting of sheet metal. It has been widely used in shipbuilding and machinery manufacturing industries. There are many factors that affect the cutting quality of CNC plasma cutting machines. In addition to the design parameters of the cutting machine, they are also related to the operation control and cutting process. In order to improve the cutting quality, we carried out a comprehensive cutting test, analyzed and sorted out according to the test data, and obtained some of the best working parameters of the CNC plasma cutting machine.