(1) High precision, fast speed, narrow slit, minimum heat affected zone, smooth cut surface and no burr.

(2) The laser cutting head does not come into contact with the surface of the material and does not scratch the workpiece.

(3) The slit is the narrowest, the heat affected zone is the smallest, the local deformation of the workpiece is very small, and there is no mechanical deformation.

(4) It has good processing flexibility, can process any pattern, and can cut pipes and other profiles.

(5) Non-deformable cutting can be performed on materials of any hardness such as steel plates, stainless steel, aluminum alloy plates, and hard alloys.

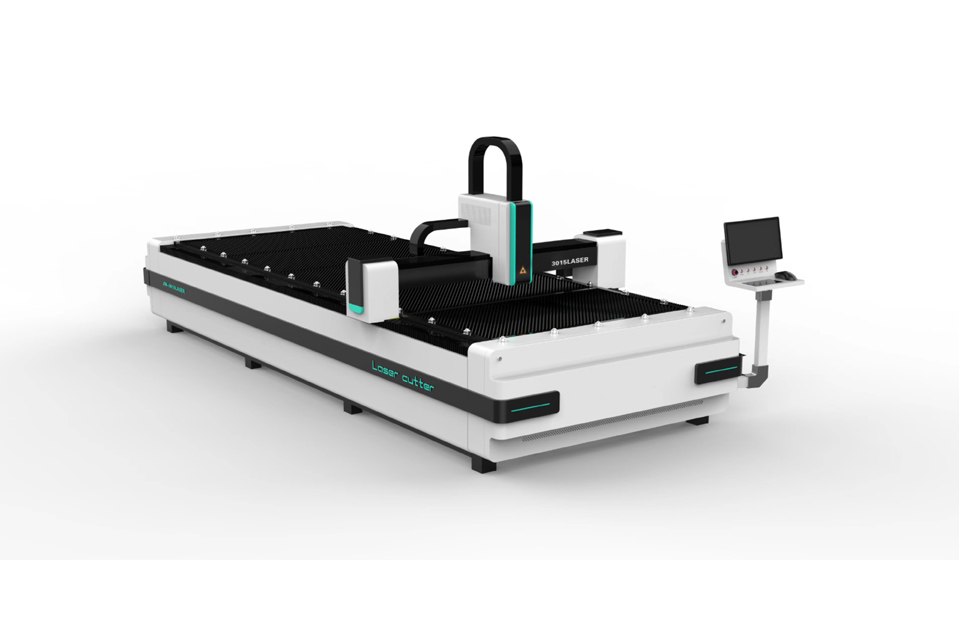

TW-3015 Fiber laser Cutting Machine meets the parts processing requirements of most industries, working accuracy is stable. At present,laser cutting machines have been widely used in electronics, electrical,mechanical hardware, new energy lithium, packaging, solar, LED, automotive and other industries.

| Machine Model | TW3015 | |

| Cutting Area(length x width) | 3000mm×1500mm | |

| Laser Model | Fiber laser IPG-500W/1000W | |

| Laser Wavelength | 1,070-1,080nm | |

| CS Cutting Thickness | Max. 5mm/10mm | |

| SS Cutting Thickness | Max. 3mm/5mm | |

| Interface | USB,RJ45 | |

| X-Axis | Moving Speed | 50m/min |

| Stroke | 3000mm | |

| Position Accuracy | ±0.05mm/m | |

| Repeatability Accuracy | 0.05mm | |

| Y-Axis | Moving Speed | 50m/min |

| Stroke | 1500mm | |

| Position Accuracy | ±0.05mm/m | |

| Repeatability Accuracy | 0.05mm | |

| Z-Axis | Stroke | 50mm |

| Power Supply Requirement | 400V/50Hz/30A(36A) | |

| Continuous Working Time | 24Hours | |

| Machine Weight | Approximate 4000kg | |

| Dimension(length×width×height) | 4500mm×2300mm×1500mm | |

Used in sheet metal processing, aviation, aerospace, electronics,electrical appliances, subway parts, automobiles, grain machinery, textile machinery, engineering machinery, precision parts, ships,